Views: 4 Author: Site Editor Publish Time: 2021-06-09 Origin: Site

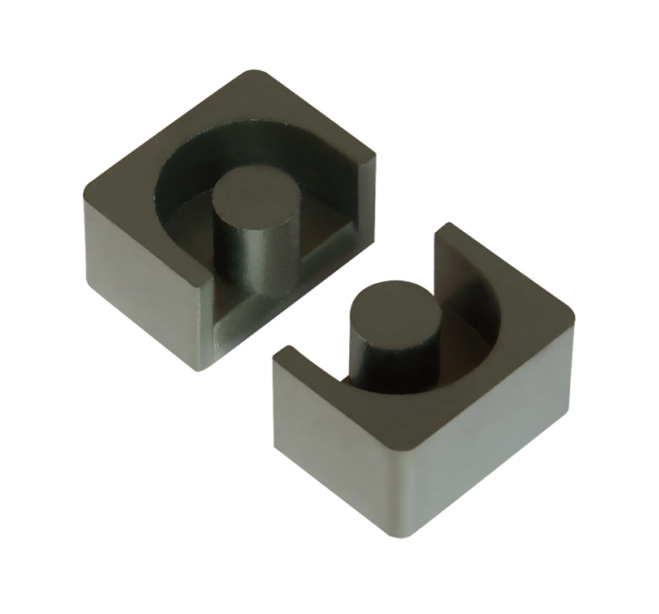

A polypropylene (PP) ferrite core is an extremely versatile, lightweight core that is used for a wide range of applications in both commercial and industrial settings. A core may be either closed or open ended, depending on the manufacturer's specifications. While most PQ ferrite cores have a closed configuration, some manufacturers can also supply open ended cores which are fully adjustable to flat or curved shapes. The PP core is very useful for many different applications due to its light weight, flexibility and excellent conductivity properties. As a result of its many applications, the core is used in a wide range of equipment, machinery and components, from drills to turbine engines.

This versatile material has several physical and chemical properties which make it a very useful tool for heat pipe applications. A thermal insulation property of PP Ferrite core is unique in that it contains an extremely fine and thin layer of ferrite that is separated by a layer of oxygen. This gives the core the ability to achieve thermal mass within a very small space, making it ideal for thermal insulation of highly stressed and exposed parts. The thermal mass of the ferrite core allows the material to retain its shape during any type of stress or temperature change. This unique property can prevent warping and heating damage to any part which may be subjected to a change of environment.

An application of the ferrite core can be a flexible, ductile and lightweight alternative to other materials such as steel, aluminum, brass and bronze which may provide a more economical, efficient solution when high temperatures are applied. PP core is also commonly used in conjunction with stainless steel for heat treatment, where it can also provide an effective method of preventing corrosion and rusting. Heat treatment and heat conduction are also a popular use of the core, as it can also be applied to precision machined components, such as precision bearings.

Another potential application for the ferrite core is as an expansion joint in forging and sheet metal fabrication. The heating and cooling process can be accelerated, as well as the stresses placed on the parts being formed can be reduced. It is also useful for use in electrical panel insulation and heat exchange applications.

Ferrite cores have the ability to exhibit electromagnetic field emission. When applied as a liner to tubing and tank covers, it has the ability to enhance the heat conduction between the coating and the metal layers around it. It also exhibits superior dielectric properties, which allows it to be used in many different applications. The core has also been found to exhibit superior elasticity, compared to pure ferrous alloys which have better thermal conductivity properties.

PPQ flux cored tubes are frequently used in heating applications, as they exhibit the same excellent electrical and mechanical properties as steel and copper. They are also commonly used in the automotive and aerospace industries to reduce weight and increase lubrication. Other common uses include air bags, seals for doors and various packaging applications. This core is also used in some CAD applications, as it is highly resistance to corrosion.