Views: 6 Author: Site Editor Publish Time: 2021-09-14 Origin: Site

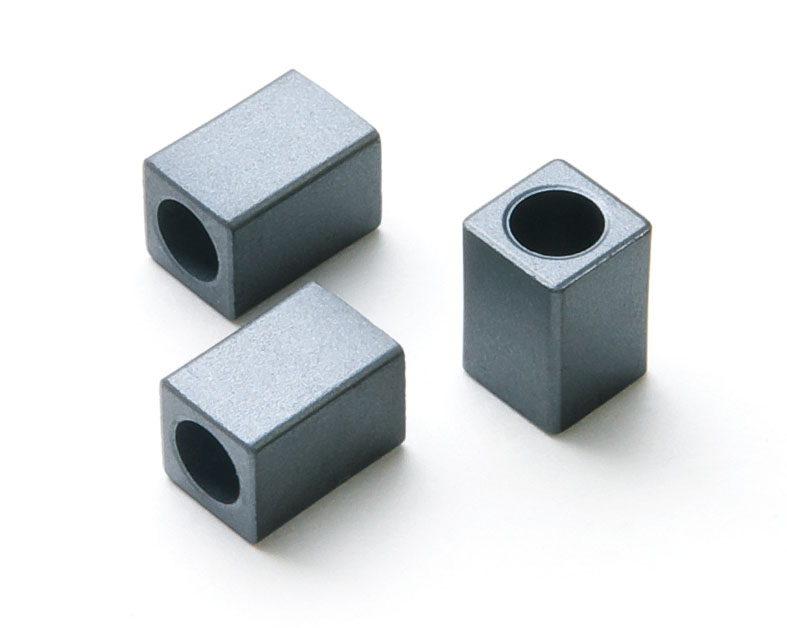

A new generation ferrite iron core ferrous iron core is now available in the market. It offers numerous benefits over traditional ferrous products. The ferrite iron core is highly demanded for its extreme hardness, superlative corrosion resistance, high temperature resistance, magnetism and magnetic properties. It is mostly used in aerospace, power generation, electronic applications, Ferricraft and high-frequency components. Due to its extreme durability and cost effectiveness, this ferrite iron core is widely used in abrasive cutting tools, drilling equipment, and fasteners.

This ferrite iron core is available as a powder or a core and it is also possible to customize the thickness of the ferrite particles by adding some percentage of other powdered ferrite salts. These powders and additives are blended with other powdered materials such as silicon, aluminum oxide, calcium fluoride, boron nitride, magnesium stearate, sodium chloride, calcium carbonate, titanium powder, aluminum powder, graphite or other metallic substances and then heat-treated. After this process, the raw materials become malleable and can be easily molded into different shapes and sizes. The resulting ferrite products are then hardened by hammering and rapidly hardened into small ferrite iron cores.

In order to prevent rusting and corrosion, this ferrite iron core is often coated with a ferrite-zinc alloy layer. This layer provides additional protection against corrosion and oxidation. The surface of the ferrite iron core is highly polished for a high quality and precision, making it ideal for many applications. It is highly durable and has high tensile strength. The core of this ferrite multi tool is made of ferrous iron, but because of its unique features it is sometimes combined with high carbon alloys for high hardness and toughness. Other compounds such as boron nitride and magnesium stearate, which are commonly used as lubricants, increase its wear resistance and improve its working friction.

The ferrite tool can perform at least thirty times more function than any other material used in similar applications. This is due to its extreme ductility and its stiffness. Due to its unique properties, the ferrite-coated multi tools are used for drilling, sawing, cutting, trimming and grinding. There are various sizes and designs of this ferrite tool available in the market today. You can choose from one of the most popular designs - the "Tungsten Carbide Plier".

Many professional companies manufacture these specialized ferrite tools. You can find a wide range of models on the market. Some of these brands include Babco PMC, Hitachi Ltd., Hitachi Metalsurgical Power Products Co. Ltd., K&N Engineering Co. Ltd., Festool Ltd., Ferrox International Ltd., Hammarrack Ltd., JML Ltd., etc. These companies focus on providing cost-efficient solutions and a comprehensive after sales service. Some of these companies also provide worldwide services to their customers. In addition to this, they ensure quality and safety at all their manufacturing plants.

A reliable tool is always useful. The ferrite tools help us cut down the cost as we do not require a large investment. However, before you select any tool, make sure that it has passed the toughest tests. It is always better to select a tool based on its performance rather than its looks. Inferior looking tools often malfunction or cause other hazardous situation at the work place.